Value Chain

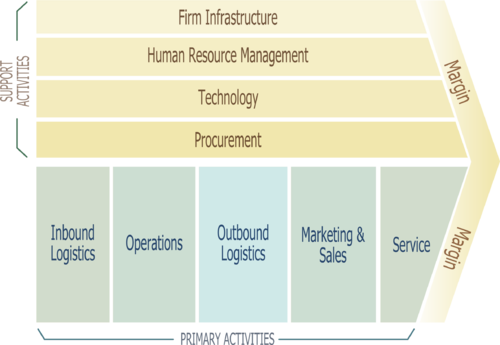

A value chain is a set of activities that a firm operating in a specific industry performs in order to deliver a valuable product or service for the market. The concept comes from business management and was first described and popularized by Michael Porter in his 1985 best-seller, Competitive Advantage: Creating and Sustaining Superior Performance.[1]The idea of the value chain is based on the process view of organizations, the idea of seeing a manufacturing (or service) organization as a system, made up of subsystems each with inputs, transformation processes and outputs. Inputs, transformation processes, and outputs involve the acquisition and consumption of resources - money, labour, materials, equipment, buildings, land, administration and management. How value chain activities are carried out determines costs and affects profits.The concept of value chains as decision support tools, was added onto the competitive strategies paradigm developed by Porter as early as 1979.[dubious ][3] In Porter's value chains, Inbound Logistics, Operations, Outbound Logistics, Marketing and Sales, and Service are categorized as primary activities. Secondary activities include Procurement, Human Resource management, Technological Development and Infrastructure (Porter 1985, pp. 11–15).[1][2]

— IfM, Cambridge[2]

According to the OECD Secretary-General (Gurría 2012)[4] the emergence of global value chains (GVCs) in the late 1990s provided a catalyst for accelerated change in the landscape of international investment and trade, with major, far-reaching consequences on governments as well as enterprises (Gurría 2012).[4]

Firm-level

Michael Porter's Value Chain

The activity of a diamond cutter can illustrate the difference between cost and the value chain. The cutting activity may have a low cost, but the activity adds much of the value to the end product, since a rough diamond is significantly less valuable than a cut diamond. Typically, the described value chain and the documentation of processes, assessment and auditing of adherence to the process routines are at the core of the quality certification of the business, e.g. ISO 9001.[citation needed]

A firm's value chain forms a part of a larger stream of activities, which Porter calls a value system[citation needed]. A value system, or an industry value chain, includes the suppliers that provide the inputs necessary to the firm along with their value chains. After the firm creates products, these products pass through the value chains of distributors (which also have their own value chains), all the way to the customers. All parts of these chains are included in the value system. To achieve and sustain a competitive advantage, and to support that advantage with information technologies, a firm must understand every component of this value system.[citation needed]

Primary activities

- Inbound Logistics: arranging the inbound movement of materials, parts, and/or finished inventory from suppliers to manufacturing or assembly plants, warehouses, or retail stores

- Operations: concerned with managing the process that converts inputs (in the forms of raw materials, labor, and energy) into outputs (in the form of goods and/or services).

- Outbound Logistics: is the process related to the storage and movement of the final product and the related information flows from the end of the production line to the end user

- Marketing and Sales: selling a product or service and processes for creating, communicating, delivering, and exchanging offerings that have value for customers, clients, partners, and society at large.

- Service: includes all the activities required to keep the product/service working effectively for the buyer after it is sold and delivered.

Support activities

- Procurement: the acquisition of goods, services or works from an outside external source

- Human Resources Management: consists of all activities involved in recruiting, hiring, training, developing, compensating and (if necessary) dismissing or laying off personnel.

- Technological Development: pertains to the equipment, hardware, software, procedures and technical knowledge brought to bear in the firm's transformation of inputs into outputs.

- Infrastructure: consists of activities such as accounting, legal, finance, control, public relations, quality assurance and general (strategic) management.

Physical, virtual and combined value chain

Competitive advantage cannot be understood by looking at a firm as a

whole. It stems from the many discrete activities a firm performs in

designing, producing, marketing, delivering and supporting its product.

Each of these activities can contribute to a firm's relative cost

position and create a basis for differentiation.

- Physical/traditional value chain: a physical-world activity performed in order to enhance a product or a service. Such activities evolved over time by the experience people gained from their business conduct. As the will to earn higher profit drives any business,[citation needed] professionals (trained/untrained) practice these to achieve their goal.

- Virtual value chain: The advent of computer-based business-aided systems in the modern world has led to a completely new horizon of market space in modern business-jargon - the cyber-market space. Like any other field of computer application, here also we have tried to implement our physical world's practices to improve this digital world. All activities of persistent physical world's physical value-chain enhancement process, which we implement in the cyber-market, are in general terms referred to[by whom?] as a virtual value chain.

Combined Value Chain = Physical Value shown in sample below.

| Inbound Logistics | Production Process | Out-Bound Logistics | Marketing | Sales | Activities |

|---|---|---|---|---|---|

| GATHER | |||||

| ORGANIZE | |||||

| SELECT | |||||

| SYNTHESIZE | |||||

| DISTRIBUTE |

Industry-level

An industry value-chain is a physical representation of the various processes involved in producing goods (and services), starting with raw materials and ending with the delivered product (also known as the supply chain). It is based on the notion of value-added at the link (read: stage of production) level. The sum total of link-level value-added yields total value. The French Physiocrats' Tableau économique is one of the earliest examples of a value chain. Wasilly Leontief's Input-Output tables, published in the 1950s, provide estimates of the relative importance of each individual link in industry-level value-chains for the U.S. economy.Global value chains (GVCs)

Main article: Global value chain

Cross border / cross region value chains

Often multinational enterprises (MNEs) developed global value chains, investing abroad and establishing affiliates that provided critical support to remaining activities at home. To enhance efficiency and to optimize profits, multinational enterprises locate "research, development, design, assembly, production of parts, marketing and branding" activities in different countries around the globe. MNEs offshore labour-intensive activities to China and Mexico, for example, where the cost of labor is the lowest.(Gurría 2012)[4] the emergence of global value chains (GVCs) in the late 1990s provided a catalyst for accelerated change in the landscape of international investment and trade, with major, far-reaching consequences on governments as well as enterprises.(Gurría 2012)[4]Global value chains (GVCs) in development

Through global value chains, there has been growth in interconnectedness as MNEs play an increasingly larger role in the internationalisation of business. In response, governments have cut Corporate income tax (CIT) rates or introduced new incentives for research and development to compete in this changing geopolitical landscape.(LeBlanc et al. 6)[7]In an (industrial) development context, the concepts of Global Value Chain analysis were first introduced in the 1990s (Gereffi et al.)[8] and have gradually been integrated into development policy by the World Bank, Unctad,[9] the OECD and others.

Value chain analysis has also been employed in the development sector as a means of identifying poverty reduction strategies by upgrading along the value chain.[10] Although commonly associated with export-oriented trade, development practitioners have begun to highlight the importance of developing national and intra-regional chains in addition to international ones.[11]

For example, the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) has investigated strengthening the value chain for sweet sorghum as a biofuel crop in India. Its aim in doing so was to provide a sustainable means of making ethanol that would increase the incomes of the rural poor, without sacrificing food and fodder security, while protecting the environment.[12]

Significance

The value chain framework quickly made its way to the forefront of management thought as a powerful analysis tool for strategic planning. The simpler concept of value streams, a cross-functional process which was developed over the next decade,[13] had some success in the early 1990s.[14]The value-chain concept has been extended beyond individual firms. It can apply to whole supply chains and distribution networks. The delivery of a mix of products and services to the end customer will mobilize different economic factors, each managing its own value chain. The industry wide synchronized interactions of those local value chains create an extended value chain, sometimes global in extent. Porter terms this larger interconnected system of value chains the "value system". A value system includes the value chains of a firm's supplier (and their suppliers all the way back), the firm itself, the firm distribution channels, and the firm's buyers (and presumably extended to the buyers of their products, and so on).

Capturing the value generated along the chain is the new approach taken by many management strategists. For example, a manufacturer might require its parts suppliers to be located nearby its assembly plant to minimize the cost of transportation. By exploiting the upstream and downstream information flowing along the value chain, the firms may try to bypass the intermediaries creating new business models, or in other ways create improvements in its value system.

Value chain analysis has also been successfully used in large petrochemical plant maintenance organizations to show how work selection, work planning, work scheduling and finally work execution can (when considered as elements of chains) help drive lean approaches to maintenance. The Maintenance Value Chain approach is particularly successful when used as a tool for helping change management as it is seen as more user-friendly than other business process tools.

A value chain approach could also offer a meaningful alternative to evaluate private or public companies when there is a lack of publicly known data from direct competition, where the subject company is compared with, for example, a known downstream industry to have a good feel of its value by building useful correlations with its downstream companies.

Use with other Analysis Tools

| This section does not cite any sources. (September 2014) |

For example, a SWOT analysis can be used within the "Outbound Logistics" Function to understand what its strengths and weaknesses are, and what opportunities there may be to improve that area, or identify the threats to what may be a critical part of the value delivery system.

Equally, other models can be used to assess performance, risk, market potential, environmental waste, etc.

SCOR

The Supply-Chain Council, a global trade consortium in operation with over 700 member companies, governmental, academic, and consulting groups participating in the last 10 years, manages the Supply-Chain Operations Reference (SCOR), the de facto universal reference model for Supply Chain including Planning, Procurement, Manufacturing, Order Management, Logistics, Returns, and Retail; Product and Service Design including Design Planning, Research, Prototyping, Integration, Launch and Revision, and Sales including CRM, Service Support, Sales, and Contract Management which are congruent to the Porter framework. The SCOR framework has been adopted by hundreds of companies as well as national entities as a standard for business excellence, and the U.S. Department of Defense has adopted the newly launched Design-Chain Operations Reference (DCOR) framework for product design as a standard to use for managing their development processes. In addition to process elements, these reference frameworks also maintain a vast database of standard process metrics aligned to the Porter model, as well as a large and constantly researched database of prescriptive universal best practices for process execution.Value Reference Model

A Value Reference Model (VRM) developed by the trade consortium Value Chain Group offers a proprietary information model for value chain management, encompassing the process domains of product development, customer relations and supply networks.The integrated process framework guides the modeling, design, and measurement of business performance by uniquely encompassing the plan, govern and execute requirements for the design, product, and customer aspects of business.

The Value Chain Group claims VRM to be next generation Business Process Management that enables value reference modeling of all business processes and provides product excellence, operations excellence, and customer excellence.

Six business functions of the value chain:

- Research and development

- Design of products, services, or processes

- Production

- Marketing and sales

- Distribution

- Customer service

Post A Comment:

0 comments: